Leak Detection

The CETA test devices are using compressed air as test medium. The viscosity of air is smaller than the viscosity of fluids. Therefore the test medium air can be used to check, if the test part is leakproof against water or oil. Using the differential pressure method the smallest detectable leak rates are 0,001 mbar*l/s. As the pressure in the test part volume is compared to the pressure in a tight reference volume, a pressure decay of about 1 Pa/s can be resolved. If the test part volume is less than 100 cm³ a leak rate of 0,001 mbar*l/s can be detected. Depending on the concrete requirements of the test procedure, the test pressures are between –1 bar and +30 bar (gage pressure).

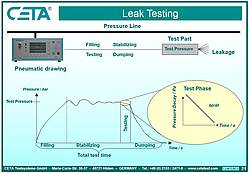

The leak detector controls the complete test procedure, which consists of the following successive phases: 1) in the filling phase the test part is filled with air until the test pressure is reached, 2) the stabilising phase, in which the pressure fluctuations in the test part calm down. In 3) the testing phase a differential pressure sensor is switched into the measuring circuit and the pressure decay caused by the leakage is registrated. And finally in 4) the dumping phase the test part is vented. The pressure decay registered in the testing phase is compared to the evaluation limits. If the leakage is within these limits the test part is evaluated as good part.

There are different test modes, which can be used in leak detection (like closed component, dynamic pressure, pressure rise). These can be applied to test specific parts and can be used to cover particular test requirements.