CETA Press releases

Test Devices and Leak Testing in Action - CETA exhibits at the Control 2024 trade fair

This year, CETA Testsysteme GmbH will once again be exhibiting at the Control 2024 trade fair from 23. to 26.04.2024 in Stuttgart. Visitors should look forward to an interesting range of products and solutions.

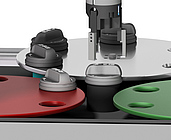

A highlight at the CETA stand is the live demonstration of leak testing of fuel tank caps in a test stand using the CETATEST 825 differential pressure tester. In the fully automated test bench, fuel tank caps are tested for leaks using negative overpressure.

You can read this article in:

February 2024

Practical knowledge for industrial leak and flow testing

CETA online seminar program "CETA Digital - From the practice for the practice"

CETA Testsysteme GmbH is a solution provider and manufacturer of test devices that are used by customers worldwide for quality assurance in leak and flow testing in the production process.

The seminar program for the first half of 2024 offers a variety of topics based on applications and issues that frequently arise in practice. These include selection, function and use of leak and flow testers. Special applications will also be covered, such as the challenges and special features of leak testing large-volume products and encapsulated products.

Fourth-generation CETA leak testers replace the previous series

Gradual product discontinuation of the CETATEST x15 test device series

For more than 35 years, CETA Testsysteme GmbH is a successful solution provider and manufacturer of test devices in the field of industrial leak and flow testing. Several thousand CETA test devices are in use worldwide for quality assurance in production lines.

With the fourth generation of leak testers, CETA has successfully launched the successor to the long-established CETATEST x15 tester series.